Geocell

Geocell

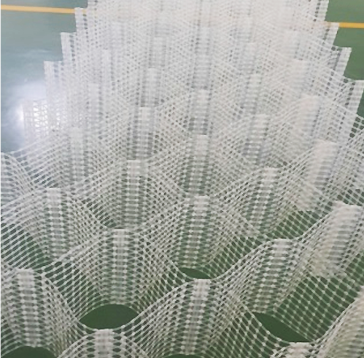

The Form of Geo-cell

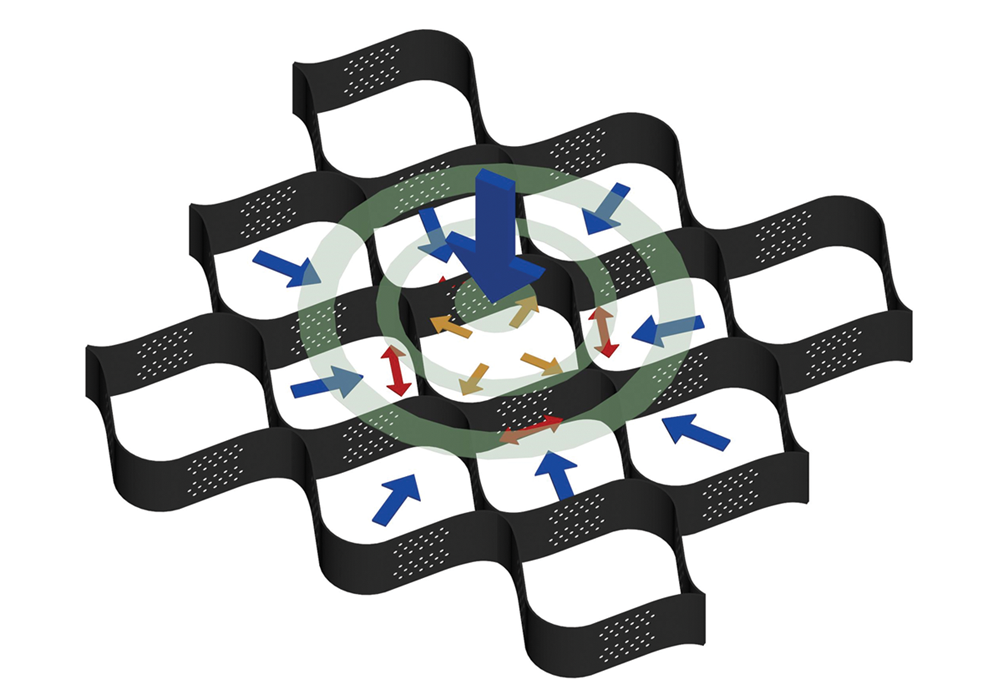

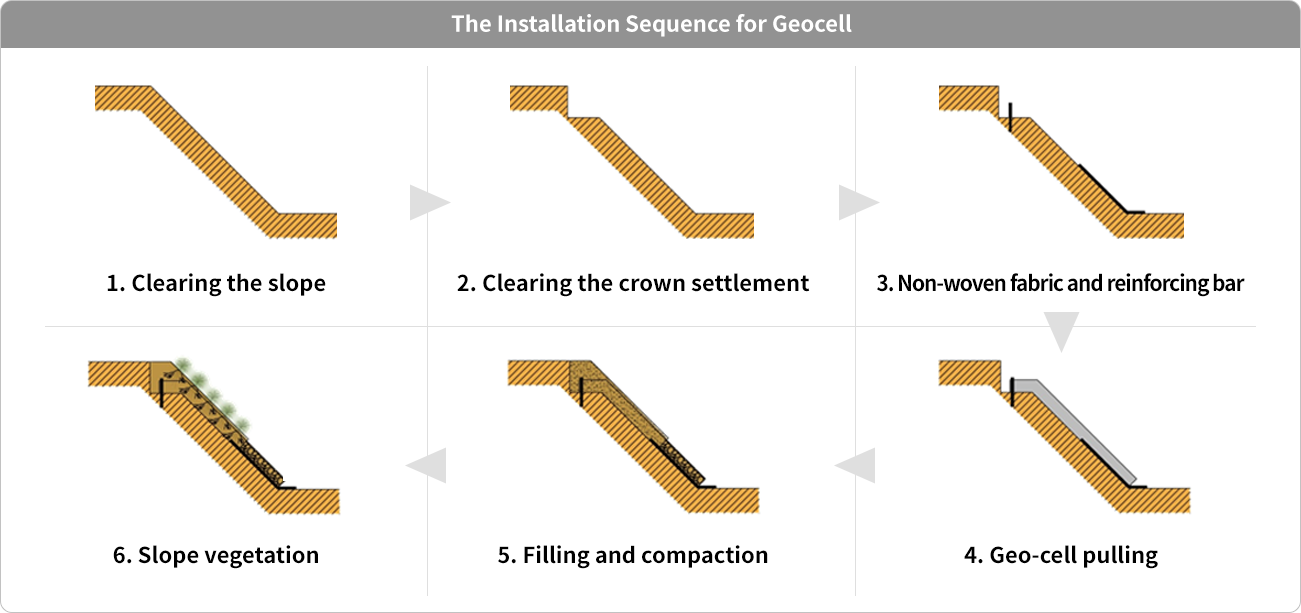

Geo-cell is a three-dimensional structure in the shape of honeycomb cells, created as a civil engineering fiber reinforcement material. By filling and compacting the infill material within each individual cell, it enhances tensile strength and cohesion properties that are unattainable by weak soils, thereby increasing the coefficient of pull-out resistance and the coefficient of friction. It utilizes natural materials such as soil and gravel as infill, as opposed to conventional concrete or other artificial materials, providing stable characteristics. It exhibits exceptional structural durability and simplifies construction, resulting in cost savings and shorter construction times.

The weak ground reinforcement of geo-cell is achieved through several factors, including the resistance of the soil infill material to external forces, frictional resistance, passive resistance from neighboring cells, and the circular stress within the cells. Additionally, high horizontal permeability contributes to the suppression of rising groundwater levels and enhances shearing strength, thereby increasing bearing capacity.

Notice

Geocell Hoan

It is a construction method used in civil engineering, where the cells of honeycomb-shaped fiber materials are filled or installed with materials such as vegetation, stones, flowable concrete, or mortar to promote vegetation growth and cover slopes.

This method allows for the use of different types of covering materials depending on the flow velocity, and it offers advantages such as shortened construction periods due to its ease of implementation. (Based on the Ministry of Land, Transport and Maritime Affairs’ River Design Standards and Commentary)

According to domestic research published in 2011

geocell revetments are considered to be safe at a flow velocity of 5m/sec. Additionally, they offer cost savings of approximately 40% compared to traditional revetments with vegetative blocks.

(It is also considered a safe revetment method for flow velocities ranging from 5m/sec to 7m/sec and tractive forces between 16kgf/㎡ to 77kgf/㎡.)

Research Paper Related to Geo-cell

-

An Experimental Study on the Applicability of Geo-cell Mats in River Revetment Facilities (Han Jin-yeong, Kim Hyun-gyeom, Kim Young-seop, Lee Gwang-su, Ahn Won-sik)

-

A Study on Stress Distribution in Weak Ground with Geo-cell Reinforcement Systems (Shin Eun-cheol, Gang Hyun-hee, Oh Young-in)

-

An Analysis of Geo-cell Reinforcement Effects on Landfill Ground through Field Tests (Kim Jong-min, Park Lee-geun, Oh Young-in, Lee Gwang-su)

-

Application of Porous Geo-cells for Railroad Subbase Reinforcement (Shin Eun-cheol, Kim Sung-hwan, Gang Jung-gu)

-

A Study on Ground Reinforcement Effects Using Porous Geo-cells (Shin Eun-cheol, Kim Sung-hwan, Kim Young-jin)

-

A Study on Eco-friendly Pavement Methods Using Geo-cells (Kim Sung-hwan, Oh Young-in)

-

Development and Characterization Study of Porous Geo-cells (Yoo Jung-jo, Oh Young-in)

The advantages of Geo-cell

-

Structural Stability

Flow velocity : 5m/sec~7m/sec

Tractive force : 16kgf/㎡~77kgf/㎡

-

Cost-Efficient Design

Geo-cells can lead to approximately 40% cost savings compared to other construction methods.

-

High Construction Efficiency

Geo-cells can reduce construction time by about 50% compared to other methods.

-

Eco-Friendly Space Creation

Vegetation rate 100%, Permeability 100%

Key Points:

-

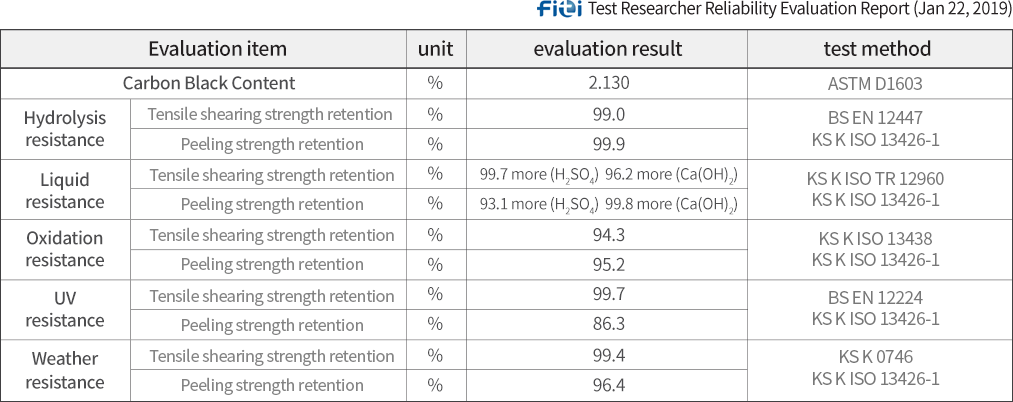

BMK Geo-cell is a high-performance product that has undergone long-term reliability evaluations across various criteria at FITI Testing and Research Institute.

-

BMK Geocell has significantly improved the issue of strength reduction at the cutting or connection points that is commonly associated with geocells by using BMK specialized connector.

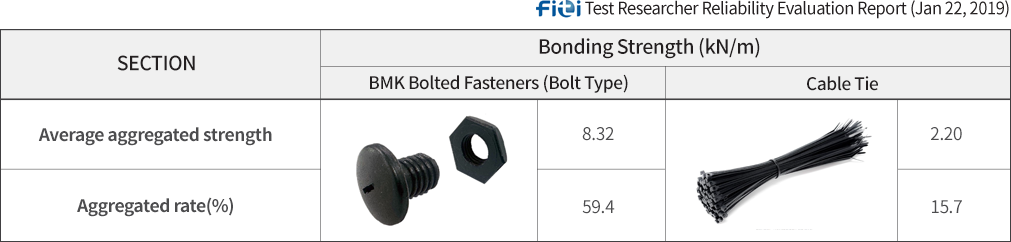

Reliability evaluation result of BMK-CELL HDPE 100% 1.2T

Bonding strength test result of BMK-CELL connector

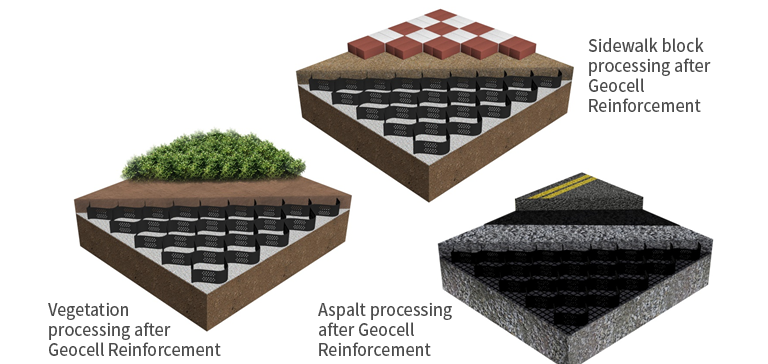

Geocell application

-

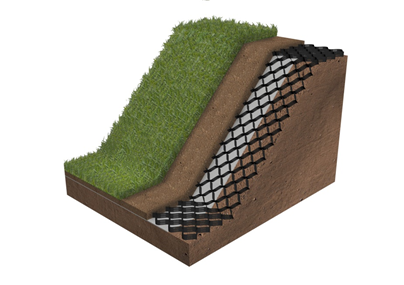

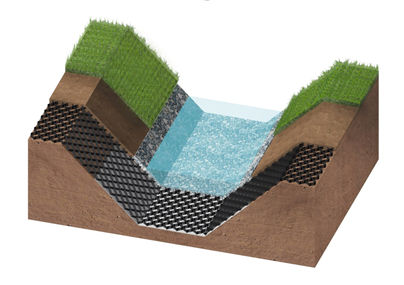

1. Reinforcement of rivers (waterways) and filling slopes

Geocell's high drainage capacity, friction and cell-soil-plant interactions prevent sliding slopes and limit the effects of shearing stress.

Perforation of geocell sheet surface promotes horizontal drainage, plant growth and root interlocking to stabilize slope and soil further and increase vegetation rate.

- River slopes, River waterway

- Cutting area, Filling slope

- Ecological river creation

- Landfill, Pond

Slope-type reinforcement

Waterway-type reinforcement

-

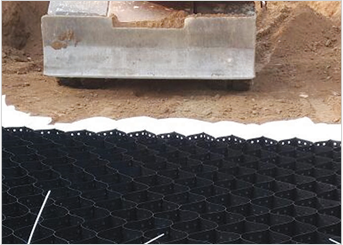

2. Soft ground and road (rail) reinforcement

Since Geocell forms a high rigidity rigid foundation and minimizes displacement and settlement by loads, it has been applied to reinforce roads, railroads, etc.

Compared to the general road design method, the gravel base thickness can be reduced by about 50% or more and the long-term performance can be improved.

- Pavement of a road

- Walkway, Trail, Cart Road

- Parking lot, Playground

- Railway, Soft Ground Temporary Road

- Building foundation and Seismic reinforcement

-

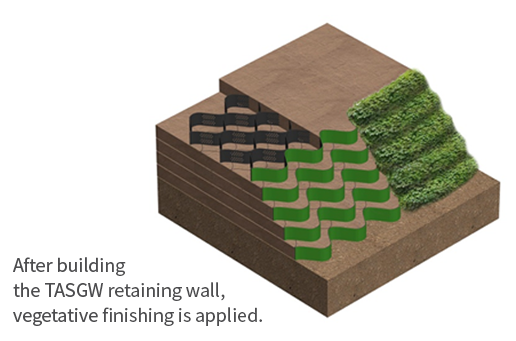

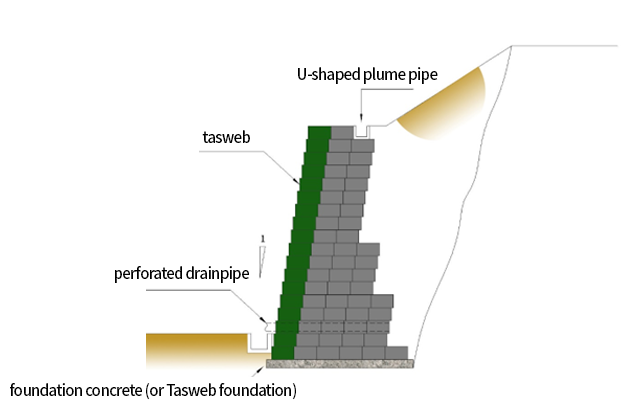

3. Vegetated Wall Construction: TASGW

Walls formed using the TASGW® system are both economical and environmentally friendly alternatives to earth retaining wall, naturally creating vegetation. They meet all structural design requirements.

TASGW® also exhibits excellent on-site adaptability. It performs well in soil environments with weak ground conditions and seismic zones. It is outstanding with the allowable differential settlement rather than front wall structure of rigid reinforced earth retaining wall. It is constructed as a gravity structure in areas with space constraints and is made of environmentally friendly HDPE.

-

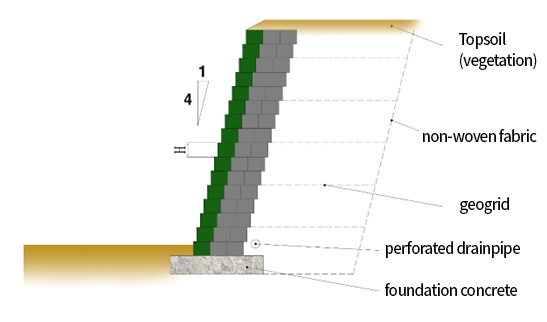

Fill-up section

1.Reinforced Retaining Wall Type

2.Gravity Retaining Wall Type

TASGW® Vegetated Retaining Walls can incorporate geo-grids or other materials such as geotextiles or strip-type fiber reinforcement during the design phase. This integration allows for the creation of stable soil structures that are fully integrated with Using the selected reinforcement material, form a reinforced earth retaining wall during the backfilling process with vertical and horizontal design interval. The TASGW® wall forming the front wall structure is a gravity structure consisting of a minimum depth of three cells, designed to resist soil pressure.

-

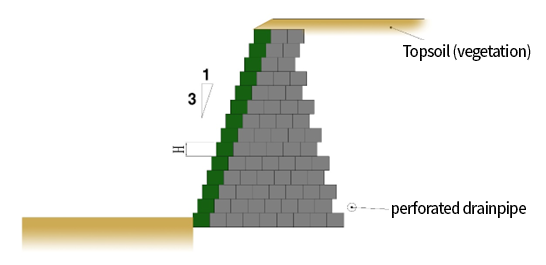

Cutting Section

1. Sloped gravity-type reinforced retaining wall

TASGW® gravity retaining wall is used when reinforcement materials cannot be applied within the reinforced soil due to constraints imposed by site back space and interference with embedded structures. The system mentioned above is constructed through layer compaction and serves as a gravity retaining wall structure that resists soil pressures on the back space. It maintains stability even under differential settlement and seismic conditions.

-

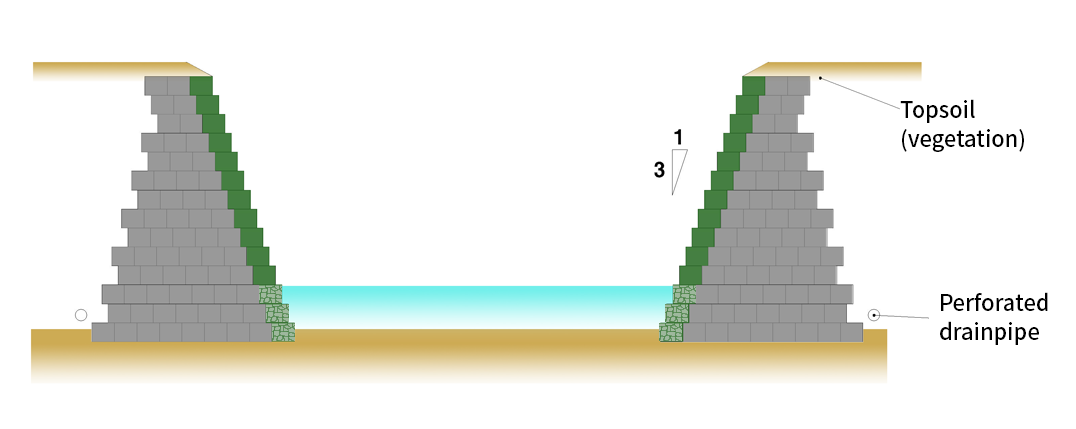

River Bank

1.River Bank

On the side slopes of TASGW®, the front wall structure incorporates plant-based filling material, providing a natural appearance. It ensures stability, from the foundation settlement to erosion conditions, while maintaining the stability of the front wall structure and the foundation.

TASGW® provides a passage for the flow of rivers through the space between its two-sided walls. In cases where the flow velocity is high, TASGW® can be filled with aggregate or concrete on the front wall structure or installed with coir fiber to reduce the potential for soil loss during the establishment and growth of vegetation.

-

-

4. Dedicated to rock and scour prevention

- Geocell is easy for granite weathering, crushed stone and dark rock.

- It can produce up to 90m/m in height and 1,000m/min height.

- Low elongation high strength geocell (honeycomb)network product has been applied with the first polyester (PET) material.

- Strict quality control of less than 8% of tensile elongation

- No friction or destruction caused by heavy equipment,crushed stone or rock, therefore the permanent structure is suitable for safety.

- It prevents deformation such as erosion caused by running water and damage occurred by external impacts from the scour.

- The purpose is to prevent the scour caused by the falling of slopes and paces.

- Running water flow is free by porous network structure.

- Since the numerical aperture is more than 80%, the drainage is smooth and prevents the separation of the filling materials such as crushed stone and rock.

- It prevents the groundwater from being swept out by the soil when it is emitted through the slope and soil grows well because the soil (slope) is where the plant can inhabit in a good condition.

- Certified as green technology